Laboratory Details - Department of Battery and Chemical Engineering

Laboratory Details

Solid-State Battery & Materials Laboratory (Prof. Ohmin Kwon)

| Fields | Research Topics | Research Results |

|---|---|---|

| High-power ASSBs |

High-power All-Solid-State Battery (ASSB) research aims to implement fast charging and discharging by applying optimized Structural and Interfacial Modifications technologies. Specifically, the focus is on precisely designing the bulk properties of the anode and cathode and optimizing the solid-state interface to minimize resistance and realize fast ion transfer characteristics. |

|

| Materials for LiBs (active materials, solvent, binder, etc) |

We are developing key cathode materials using bulk synthesis and surface modification for next-gen batteries. Our focus is a low-cost, manganese-rich (Mn-rich) composition to reduce manufacturing costs while maintaining high performance. We are also pioneering environmentally friendly manufacturing through dry electrode process technology. | |

| Long-cycle-life ASSBs (cathode, anode) |

To realize long-life All-Solid-State Batteries (ASSBs), this research aims to precisely control the bulk properties of various cathodes, such as NCM-based, Mn-rich, and LFP, as well as the anode and solid electrolyte. By conducting core research that stabilizes the interfaces between each component through stabilization of the bulk structure, the effort focuses on mitigating performance degradation and securing excellent long-term performance. | |

| Pouch cell evaluation | We aim to secure high evaluation reliability through sulfide-based All-Solid-State Battery (ASSB) pouch cells, understand the practical issues that arise during real-world application, and propose ultimate solutions. Specifically, we are conducting in-depth research on the stress problems that occur during the high-densification process and the practical difficulties encountered when applying low external stack pressure. | |

| Structural analysis | We secure high analytical reliability by combining various spectroscopy techniques with structural and crystallographic analysis. This comprehensive approach allows us to fully elucidate the lithium ion conduction mechanism and clearly identify the degradation pathways, enabling a truly holistic research effort. |

Soft Materials Research and Technology (SMART) Laboratory (Prof. Baekmin Kim)

Website : http://smartlab.hanyang.ac.kr/

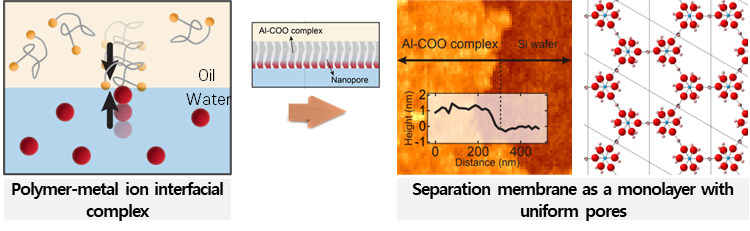

The SMART Lab at Hanyang focuses on next-generation functional material technologies centered on polymers and colloids—representative soft materials with broad applicability across diverse industries. Polymers and colloids are widely recognized as key materials in major Korean industries, including cosmetics, petrochemicals, semiconductors, and batteries, and their application range and growth potential continue to expand.

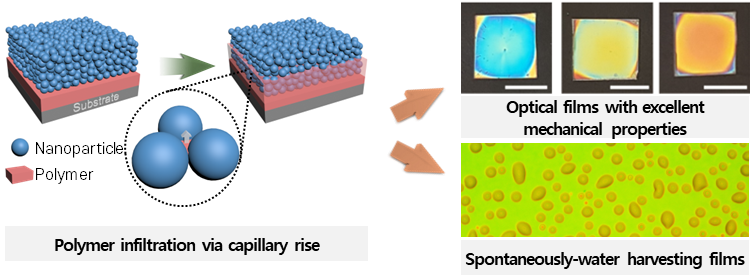

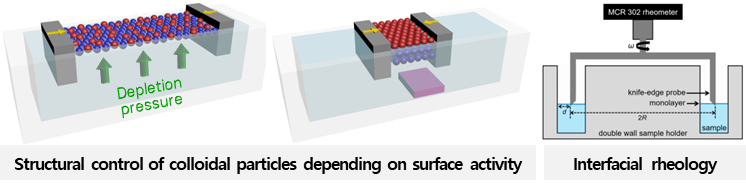

Our laboratory develops technologies that precisely control the microstructure of polymers and colloids through interfacial engineering and rheological approaches, enabling the creation of multifunctional soft materials.

- Polymer Research: We develop advanced polymer-based materials such as separators and polymer–nanoparticle composites. These materials serve as the foundation for applications including nanofilters, protective coatings, optical films, sensors, and electrode coatings.

- Colloid Research: We investigate the stabilization and mechanical property control of systems with extensive surface and interfacial areas—such as emulsions, foams, and slurries. Based on these insights, we explore practical applications in functional cosmetics, battery materials, and semiconductor materials.

| Fields | Research Topics | Research Results |

|---|---|---|

| Polymer thin films/membranes |

|

|

| Polymer-nanoparticle composites |

|

|

| Functional Colloids and rheology |

|

|

Innovative Energy Solution Laboratory (Prof. Seung-Hyeok Kim)

Website : http://seunghyeok.com/

The Innovative Energy Solution Laboratory (IESL) develops advanced lithium-ion and next-generation batteries, with a core mission to propose breakthrough solutions that deliver high energy density, enhanced safety, long cycle life, and fast-charging capability. Our strategic approaches focus on: 1) Interface engineering for stabilizing next-generation batteries such as lithium-metal systems, 2) AI-driven formation and charging protocol optimization, and 3) Development of new materials and analytical protocols to improve battery safety. Through these differentiated strategies, we aim to achieve performance metrics previously considered unattainable in conventional systems.

- Enhancing Next-Generation Battery Stability through Interface Engineering: Next-generation batteries—such as lithium-metal batteries, all-solid-state batteries, and aqueous zinc batteries—promise high energy density but suffer from interfacial instability, including dendrite formation, parasitic reactions, and limitations in fast charging. Our laboratory addresses these challenges by precisely controlling interfacial structure and composition, establishing this as a core research direction.

- AI-Driven Optimization of Formation Processes and Charging Protocols: To identify optimal formation and charging conditions, we quantify how process variables (current density, voltage, etc.) influence battery behavior and construct a comprehensive database. Using AI-based approaches, we train predictive models that learn the electrochemical responses under various formation and charging conditions. These models are then used to derive optimized protocols tailored for high performance and extended battery life.

- Development of Novel Materials and Analytical Protocols for Battery Safety: We aim to elucidate degradation mechanisms at the cell level through quantitative, reproducible, and high-fidelity analytical methods. By developing standardized protocols for assessing physical and chemical degradation, we establish reliable evaluation frameworks. Building on these insights, we design new stabilization materials and cell architectures that significantly enhance battery safety and long-term reliability.

| Fields | Research Topics | Research Results |

|---|---|---|

| Enhancing the Stability of Lithium-Metal Batteries through Interface Engineering |

|

|

| Development of High-Stability Aqueous Zinc Batteries |

|

|

| AI-Based Optimization of Formation Processes and Charging Protocols |

|

|

| Analytical Protocols and New Materials for Advanced Battery Safety |

|

NanoBio Chemistry Laboratory (Prof. Jong-Ho Kim)

Website : http://nanobiochem.hanyang.ac.kr

Professor Jong-ho Kim’s laboratory conducts research on nanobio technologies, including the synthesis of low-dimensional nanomaterials and the development of nanobiosensors capable of detecting proteins and pathogens through surface functionalization. The lab also explores nanomedicine technologies aimed at treating various diseases. Additionally, peptide synthesis using solid-phase organic synthesis is performed, with applications in functional cosmetics and biomedical materials.

Beyond nanobio technologies, the laboratory is actively engaged in the development of advanced battery materials and performance evaluation for next-generation energy storage systems, including Li-metal all-solid-state batteries, Li–S batteries, and aqueous metal–air batteries.

| Fields | Research Topics | Research Results |

|---|---|---|

| NanoBio Technology |

|

|

| Next-Generation Batteries & Electrocatalysts |

|

|

| Nanomaterials & Functional Organic Material Synthesis Technologies |

|

|

Inorganic Hybrid Materials and Nano Energy Laboratory (Prof. Hyojong Yoo)

Website : https://hjhaha73.wixsite.com/hyoogroup

Our laboratory synthesizes various inorganic composite materials, nanomaterials, and coordination polymer-based materials, analyzes their properties, and transforms them into optimized forms suitable for targeted applications. Our primary focus lies in two major areas—energy & catalysis technologies and biotechnology. We develop highly active and stable inorganic nanocomposites, design advanced catalytic and electrochemical systems, and apply these materials to energy devices, batteries, and bio-batteries.

⦁ Functional nanostructures—such as multimetallic nanoparticles, porous inorganic oxide nanoparticles, and multicomponent metal–oxide nanocomposites—offer significant potential for energy and catalytic technologies. By enabling the direct growth of coordination polymer frameworks on electrode surfaces, we greatly enhance catalytic activity for water-splitting reactions. Maximizing interfacial junction density in multimetallic electrocatalysts further broadens their application potential in energy technologies. Through these approaches, our lab is developing efficient water-splitting systems by integrating multifunctional electrocatalyst electrodes with optimized membranes.

⦁ Using tailor-made nanocarriers, we develop multifunctional nanocomposites that combine the advantages of each component into a single material. Size-selective chemical catalysts and photocatalysts provide unique functionalities not achievable with conventional materials. In parallel, we are exploring biomedical applications by employing nanocarriers loaded with therapeutic agents—particularly for enhancing drug delivery and improving treatment efficacy for neurodegenerative and brain-injury-related conditions.

⦁ Integrating multifunctional inorganic nanocomposites with 3D-printing technologies enables the development of high-performance materials, simplifies fabrication processes, and allows customization for specific applications. Our research includes creating 3D-printed electrode systems for energy storage and battery technologies, enabling more efficient utilization of multifunctional nanocomposite materials. Ongoing work includes developing 3D-printed monoliths incorporating transition-metal-based layered double hydroxides and polymer/MOF-derived carbon composites, which are applied to energy storage systems and fuel cell technologies.

| Fields | Research Topics | Research Results |

|---|---|---|

| Multifunctional Inorganic Hybrid Materials |

|

|

| Energy & Catalysis Technologies |

|

|

| Development of Energy Storage Systems Using 3D Printing Techniques |

|

|

Process Systems Engineering & Intelligence Design Laboratory (Prof. Jaewon Lee)

Website : http://psid.hanyang.ac.kr

"Process Systems Engineering & Intelligence Design (PSID) Laboratory" at Hanyang University ERICA aims to maximize the sustainability and efficiency of the future chemical industry. Our research team strives to solve challenges in key research areas, including: △Enhancing the efficiency of refining and petrochemical processes, △Optimizing sustainable clean hydrogen production processes, △Developing waste-to-energy processes, △Battery management systems, and △Developing cryogenic CO2 capture processes.

To solve these problems, we apply techniques such as Modeling, Optimization, Techno-Economic Analysis (TEA), and Life Cycle Assessment (LCA). In particular, we actively utilize artificial intelligence (AI) technologies to propose intelligent design and optimal operation strategies that overcome the limitations of conventional processes.

⦁ AI-based Modeling

We design new processes with thermodynamic and economic advantages through innovative process simulation and Techno-Economic Analysis (TEA), while comprehensively evaluating their environmental impact via Life Cycle Assessment (LCA).

⦁ AI-based Modeling

This research field enhances process efficiency and safety in highly nonlinear and complex chemical processes. It involves performing real-time prediction, soft-sensing, new catalyst development, and anomaly diagnosis using AI models.

⦁ Computational Fluid Dynamics (CFD)

We develop CFD models to analyze fluid flow and heat transfer phenomena within processes. This is also used to ensure safety by predicting explosion and gas dispersion scenarios in the event of an accident.

| Fields | Research Topics | Research Results |

|---|---|---|

| Process Design & Optimization |

|

|

| AI-based Modeling |

|

|

| Computational Fluid Dynamics (CFD) |

|

|

고분자나노소재연구실 (장영욱 교수)

웹사이트 : http://polymer.hanyang.ac.kr

고분자나노소재연구실에서는 고분자블렌드, 나노복합재료화 및 화학적개질 방법 등을 이용한 고기능성 친환경 엘라스토머 소재, 광경화형 소재 및 형상기억고분자 개발과 이들 소재들의 타겟물성 극대화를 위한 미세구조제어에 관한 연구를 수행하고 있습니다. 또한, 유관기업체 및 타 연구실과의 유기적 협력 연구를 통하여 이들 소재들을 자동차부품, 스포츠용품, 웨어러블 기기, 이차전지, 의료용기기 등에 적용하기 위한 응용연구를 진행하고 있습니다.

| 연구 분야 | 주요 연구 내용 | 연구 결과 |

|---|---|---|

| 엘라스토머 소재 (Elastomers) |

|

|

| 광경화형 소재 (Photocurable polymers |

|

|

| 형상기억고분자 (Shape memory polymer, SMP) |

|

|

Applied Functional Organic Materials Laboratory (Prof. Kuk Young Cho)

Website : http://fomlab.hanyang.ac.kr/

The Functional Organic Materials Laboratory conducts research across several key areas, including functional separators and additives, all-solid-state batteries, lithium metal batteries, electrode modification, and electrochemical characterization. Our work is dedicated to advancing the performance of lithium-ion batteries, which are widely used in applications ranging from portable electronics to electric vehicles and large-scale energy storage systems due to their high energy density.

Although Korea possesses strong manufacturing competitiveness in the global lithium-ion battery market, continued innovation is essential to meet demands for improved performance, safety, and cost efficiency. This requires extensive research and development of next-generation battery technologies capable of overcoming the limitations of conventional materials.

Our laboratory focuses on the development of functional separators and electrolyte additives aimed at enhancing the performance of lithium-ion batteries. We also investigate core materials for next-generation systems such as lithium metal batteries and all-solid-state batteries, which offer high capacity and improved safety. Additionally, we conduct research on cathode dry processing methods and strategies to enhance the structural stability of silicon anodes—an important next-generation material for high-power applications.

Based on these materials and processes, we fabricate batteries and evaluate their electrochemical properties, with particular emphasis on improving capacity retention and long-term cycling performance.

| Fields | Research Topics | Research Results |

|---|---|---|

| Functional Separators and Electrolyte Additives |

|

|

| Lithium Metal Batteries |

|

|

| All-Solid-State Batteries |

|

|

| Electrode Modification |

|

|

| Electrochemical Characterization |

|

|

Biomedical Polymer Research Laboratory (Prof. Yong Woo Cho)

Website : http://cholab.hanyang.ac.kr/

The Biomedical Polymer Research Laboratory (BPRL) develops biocompatible and functional polymeric materials for applications in medicine, pharmacology, and cosmetics. The laboratory explores a new field of research aimed at applying the unique polymers, polymer nanostructures, polymer assemblies, and supramolecular assemblies to the convergence field of chemical engineering and biotechnology. Living organisms utilize efficient nanostructures called exosomes for effective intercellular signaling. Exosomes play a crucial role in the development and spread of diseases (e.g., in the proliferation and metastasis of cancer), and in regenerative medicine, they play a crucial role in promoting the regeneration of damaged tissues and organs. Our laboratory utilizes exosomes from various living organisms (animals, humans, and plants) to develop a novel therapeutics for disease treatments and functional cosmetic materials.

- Regenerative medicine and tissue engineering using stem cells and exosomes

- Development of drug (RNA, peptide, protein) delivery systems using exosomes

- Development of functional cosmetic materials based on plant exosomes

- Development of stem cell and exosome-related medical devices

| Fields | Research Topics | Research Results |

|---|---|---|

| Stem cell exosomes |

|

|

| plant exosomes |

|

|

| Drug delivery system using exosomes |

|